Research

Advanced Metrology

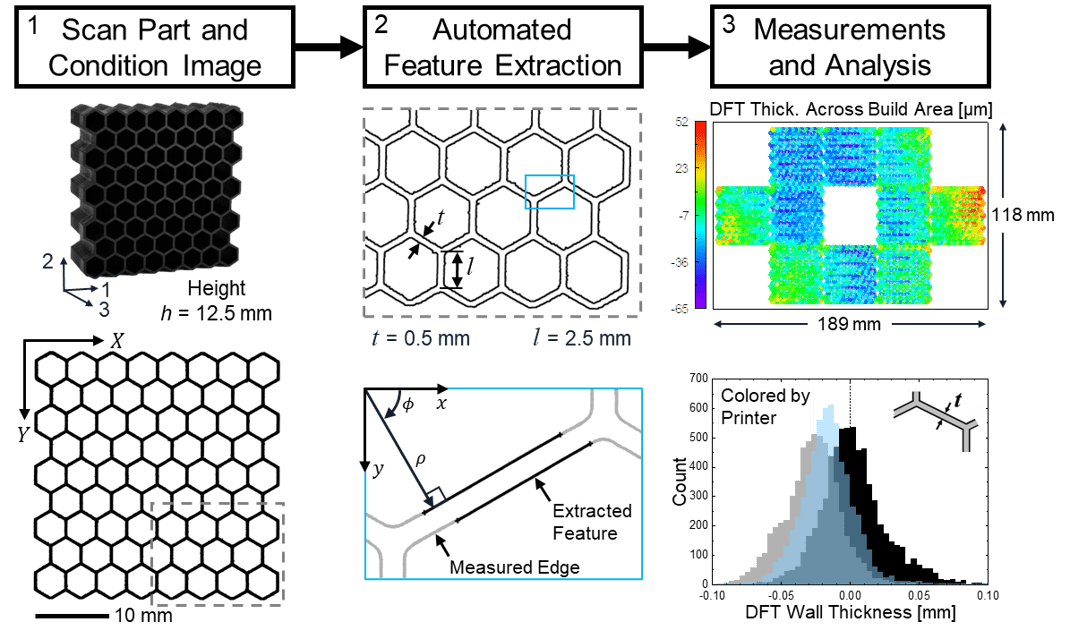

We are developing novel, automated metrology methods for measuring complex part geometries, such as those typical in additive manufacturing. Optical scan data from laser sensors, three-dimensional (3D) scanners, and photographs offer rich information and can be obtained with high speed and resolution, presenting opportunities to replace traditional tactile measurements, which are slow and require significant effort to setup and maintain. Information rich images also provide opportunities for using machine learning to discover new insights into manufacturing processes and materials physics. Our analysis techniques are data agnostic and have been applied to:

- 2D scan images and photographs

- 3D point cloud scans (variable focus microscopy, structure light, blue lasers)

- X-ray projection images and computed tomography (CT) volumes

Intelligent Manufacturing

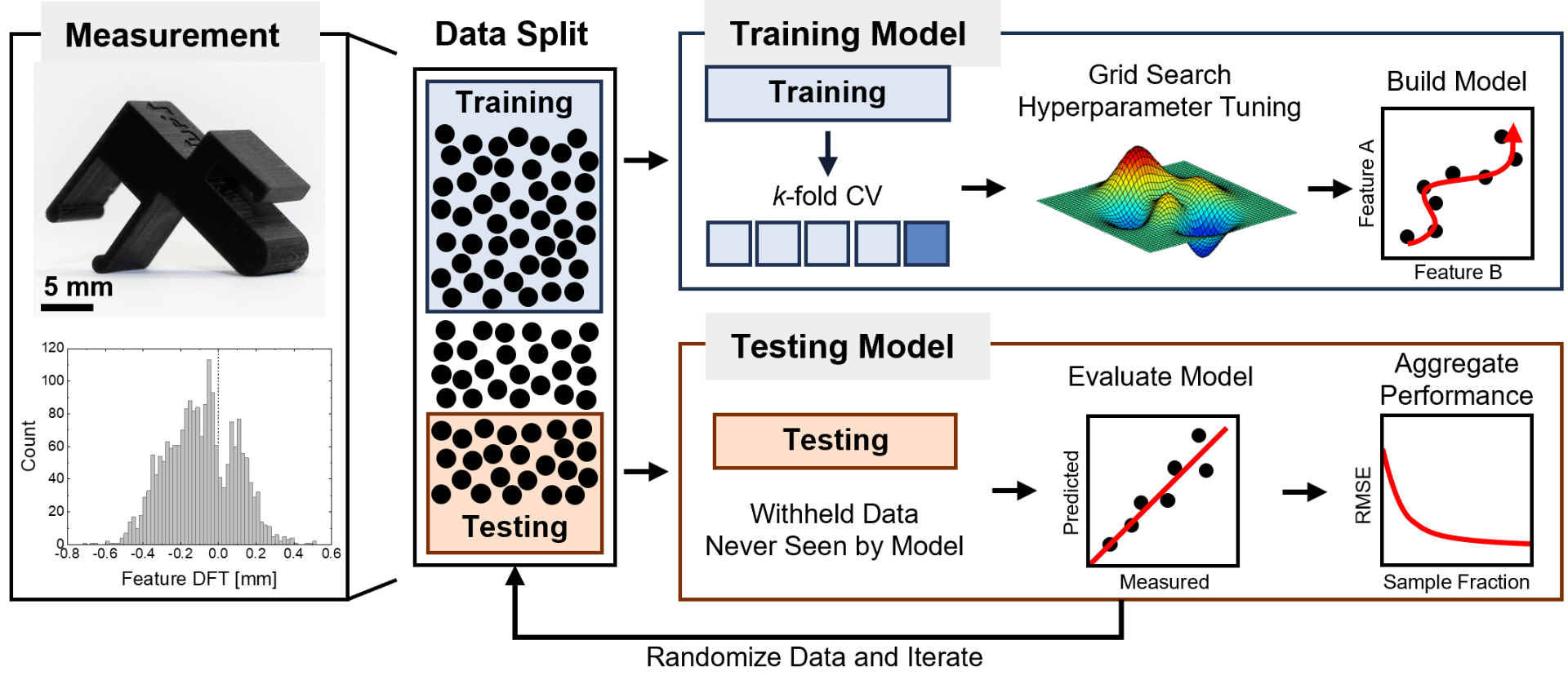

Manufacturing intelligence is defined by the leveraging of data to make better manufacturing decisions. In the MIRAGE Lab, we combine advanced metrology with artificial intelligence (AI) and computational geometry to model, predict, and improve the quality of additively manufactured parts. We use Python and open source libraries to develop state-of-the-art analysis software and intelligent models. For example:

- Rich measurement data identifies sources of manufacturing variation

- Machine learning (ML) models predict part quality

- Part designs are updated based on ML predictions to increase yield

- Continuous feedback loops enable models to learn on the fly

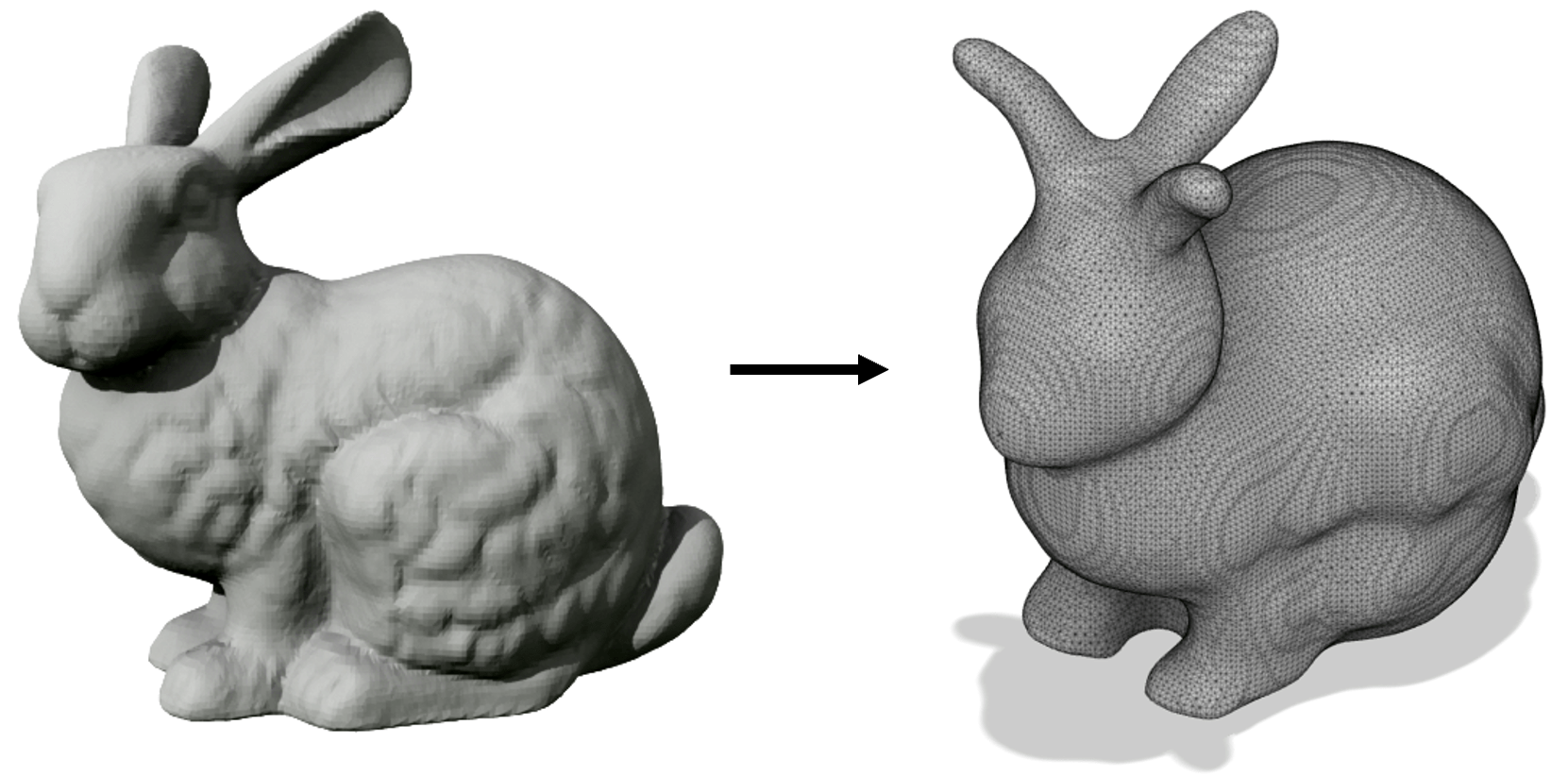

Computational Geometry

The proliferation of artificial intelligence (AI) is significantly changing the world today. While there are numerous familiar implementations, such as ChatGPT and DALL-E, applications in industrial manufacturing are just getting started. We explore the intersection of AI, design, and metrology for advanced manufacturing. Some examples include:

- Designing a part based on one or more photographs

- Part identification across 2D and 3D databases

- Modification of part designs based on manufacturability constraints

- Personalized manufacturing recommendations